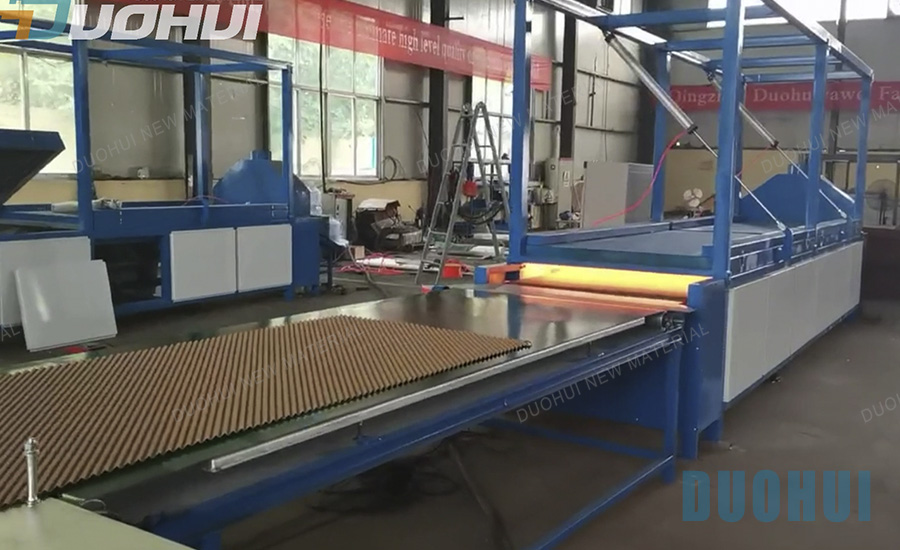

Evaporative cooling pad production line #1100 type

2024-06-28 16:11

By carefully planning and implementing these steps, you can establish a successful evaporative cooling pad production line.

Market Analysis: Understand the demand for evaporative cooling pads in your target market.

Competitor Analysis: Identify existing competitors and analyze their strengths and weaknesses.

Business Plan: Develop a comprehensive business plan outlining your goals, strategies, and financial projections.

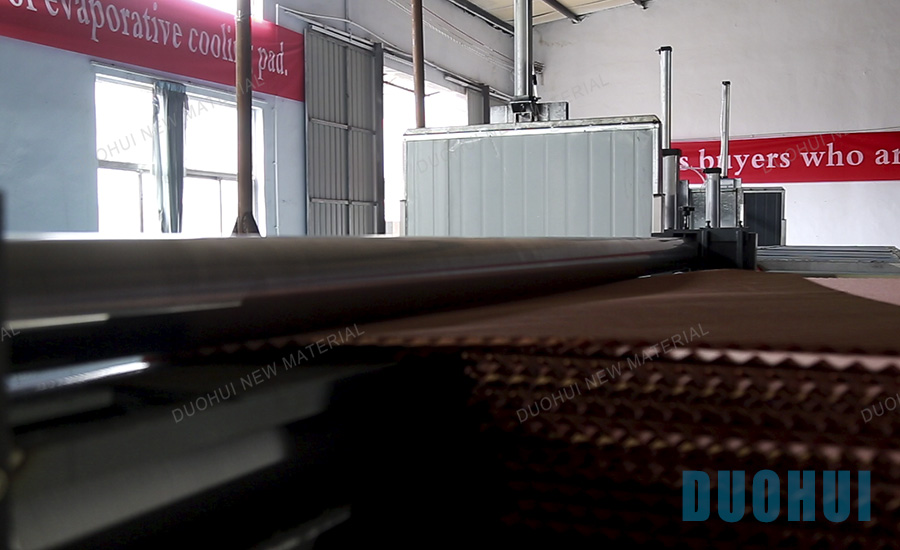

Product Design: Define the specifications of your cooling pads, including size, thickness, material, and efficiency.

Raw Materials: Identify the materials needed (e.g., cellulose paper, wood wool, or synthetic materials) and their suppliers.

Cutting Machines: For cutting the raw materials into the desired sizes.

Corrugation Machines: To create the wavy pattern that increases the surface area for better cooling.

Gluing Machines: For bonding the layers together.

Drying Ovens: To cure the glue and set the pads.

Edge Cutting Machines: To trim the edges for a neat finish.

Quality Control Equipment: For testing the efficiency and durability of the pads.

Get the latest price? We'll respond as soon as possible(within 12 hours)