Water evaporative cooling pad production line cooling pad making machine

2024-05-01 09:27

These pads, often called cooling pads or wet pads, are integral components in cooling systems for various applications such as greenhouses, poultry farms, industrial buildings, and commercial spaces. Here's an overview of the typical production line and the cooling pad making machine involved:

Material Preparation: The process begins with the preparation of raw materials. The primary material used for these cooling pads is cellulose, derived from wood pulp or other plant fibers. The cellulose material may undergo shredding, pulping, or other preparation methods to ensure it's in a suitable form for processing.

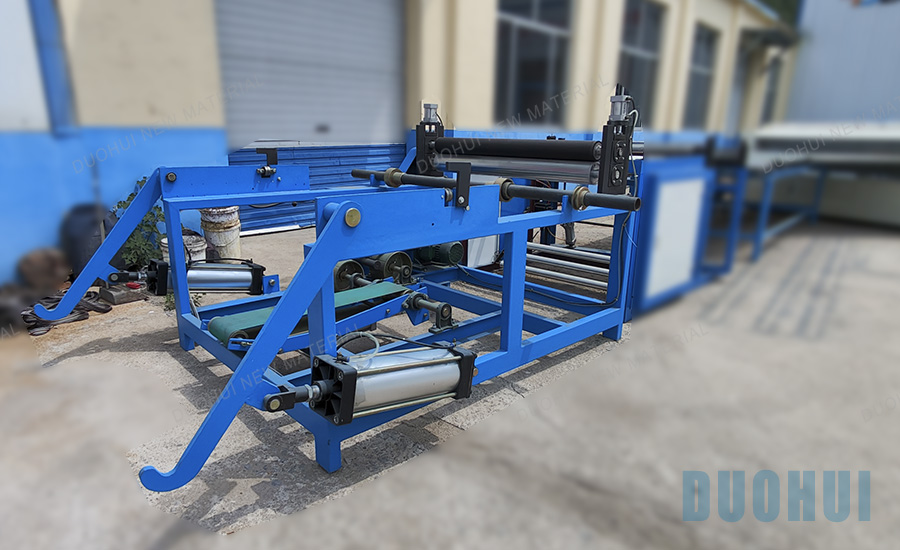

Pad Forming Machine: The prepared cellulose material is fed into a pad forming machine. This machine is designed to evenly distribute the cellulose material onto a conveyor belt or mold in the desired thickness and density. The process may involve mixing the cellulose with water to create a slurry, which is then formed into the shape of cooling pads.

Curing and Drying: Once formed, the wet cooling pads need to be cured and dried to remove excess moisture and solidify their structure. This step can be accomplished through various methods such as air drying, infrared drying, or a combination of both. Proper curing and drying are crucial for ensuring the durability and effectiveness of the cooling pads.

Cutting and Sizing: After drying, the cooling pads are cut into the desired dimensions using cutting machinery. Precision cutting ensures uniformity in size and shape, which is important for consistent performance in cooling systems. The pads may also undergo additional processing steps, such as edge trimming or shaping, to meet specific requirements.

Quality Control: Throughout the production process, quality control measures are implemented to ensure that the cooling pads meet the required standards for performance and durability. This may involve inspecting the density, thickness, pore size, and overall structural integrity of the pads. Any defective pads are identified and removed from the production line.

Packaging and Distribution: Once quality control checks are completed, the finished cooling pads are packaged and prepared for distribution to customers. Proper packaging helps protect the pads during transportation and storage until they are ready to be installed in cooling systems.

Overall, a water evaporative cooling pad production line combines specialized machinery and processes to efficiently manufacture high-quality cooling pads for various cooling applications. These pads provide effective and energy-efficient cooling by harnessing the natural process of evaporation, making them essential components in evaporative cooling systems.

Get the latest price? We'll respond as soon as possible(within 12 hours)