Hot-dip galvanizing centrifugal push pull exhaust fan

2024-05-28 09:45

High velocity push pull exhaust fan

Hot galvanized exhaust fan

Centrifugal push pull exhaust fan

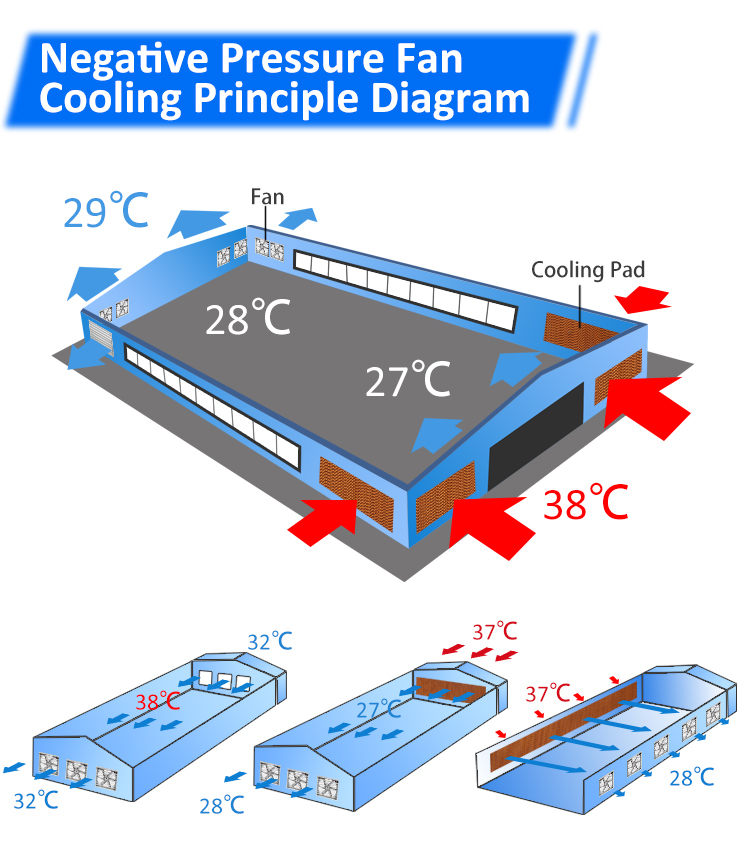

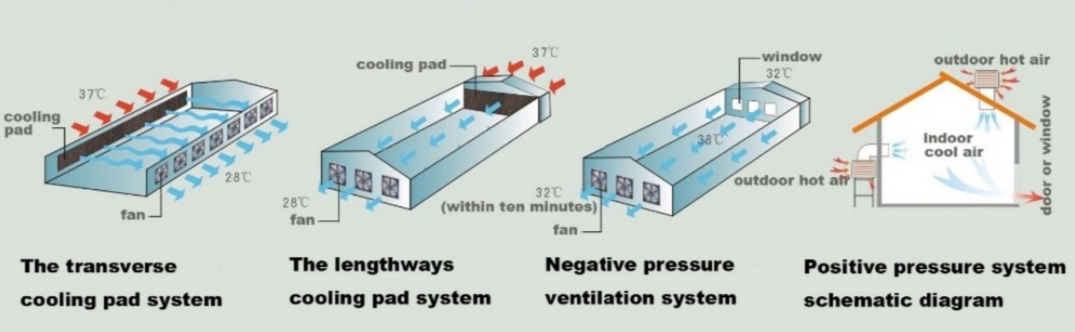

The negative pressure fan is a process that uses the principle of air convection, and the motor drives the blade fan to rotate, so that the indoor air is discharged out of the room, forming negative pressure inside the greenhouse, and the outdoor air enters the room under the action of pressure.

A hot-dip galvanized centrifugal push-pull exhaust fan is a specific type of industrial ventilation equipment designed to handle large volumes of air while being resistant to corrosion. Here’s a breakdown of its components and features:

Hot-Dip Galvanizing

Process: This involves coating steel or iron with a layer of zinc by immersing the metal in a bath of molten zinc at a temperature of around 450°C (842°F).

Benefits: Provides excellent corrosion resistance, protecting the underlying metal from rust and environmental damage. This makes it suitable for use in harsh or outdoor environments.

Centrifugal Fan

Design: Centrifugal fans, also known as radial fans, move air radially (perpendicular to the fan's intake). The fan has a rotating impeller that increases the velocity of air.

Function: They are ideal for applications requiring high pressure, such as in HVAC systems, industrial processes, and ventilation systems. They are effective at moving air against resistance.

Push-Pull System

Mechanism: In a push-pull ventilation system, one fan (the push fan) forces air into a space, while another fan (the pull fan) extracts air out. This creates a continuous airflow through the area.

Advantages: Ensures consistent air movement and can help in controlling environmental conditions like temperature, humidity, and air quality within an industrial space.

Get the latest price? We'll respond as soon as possible(within 12 hours)