Get the latest price? We'll respond as soon as possible(within 12 hours)

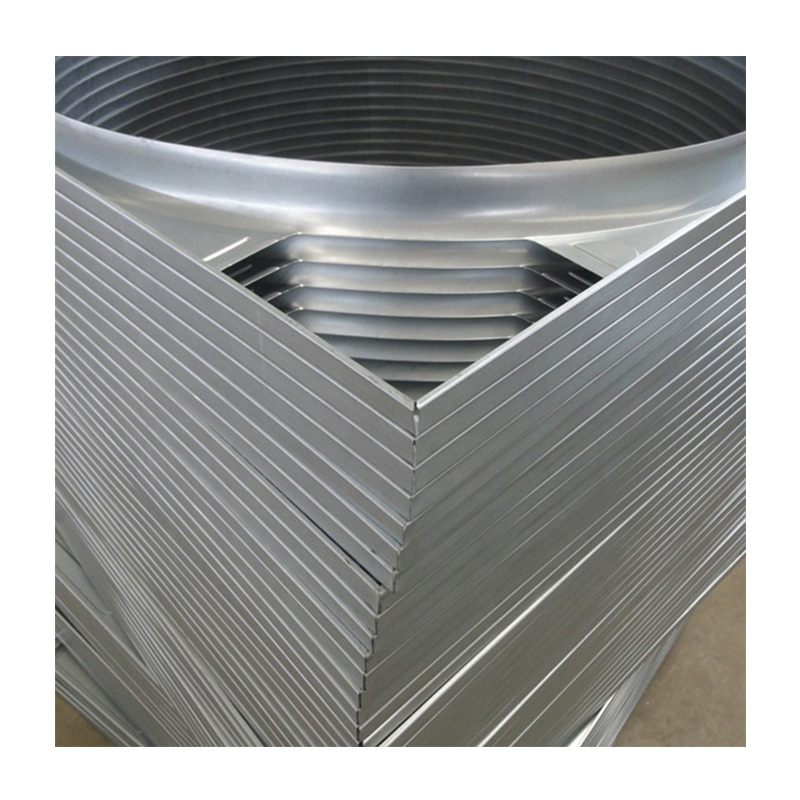

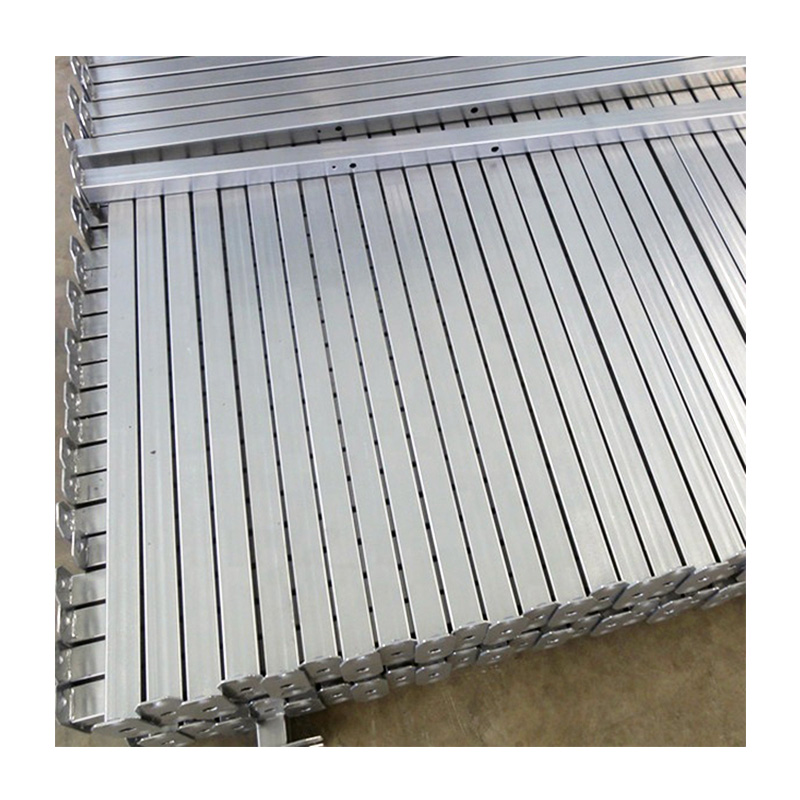

Manufacturing honeycomb pads for air cooler pads involves specialized machinery and processes tailored to create the intricate honeycomb structure that maximizes surface area for efficient cooling.

Manufacturing honeycomb pads for air cooler pads involves specialized machinery and processes tailored to create the intricate honeycomb structure that maximizes surface area for efficient cooling.

Manufacturing honeycomb pads for air cooler pads involves specialized machinery and processes tailored to create the intricate honeycomb structure that maximizes surface area for efficient cooling.

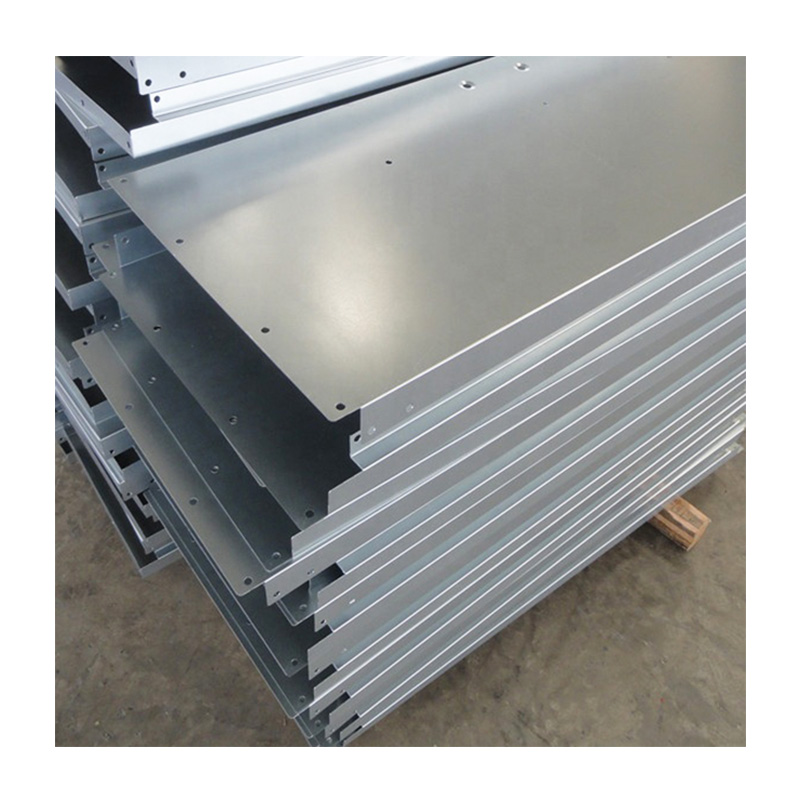

To manufacture evaporative cellulose cooling pads, specialized machinery is required to handle the unique properties of cellulose material and to ensure precise production of cooling pads.

Manufacturing honeycomb pads for air cooler pads involves specialized machinery and processes tailored to create the intricate honeycomb structure that maximizes surface area for efficient cooling.

Manufacturing honeycomb pads for air cooler pads involves specialized machinery and processes tailored to create the intricate honeycomb structure that maximizes surface area for efficient cooling.

Manufacturing honeycomb pads for air cooler pads involves specialized machinery and processes tailored to create the intricate honeycomb structure that maximizes surface area for efficient cooling.

A cellulose pad making machine is a piece of equipment used in the manufacturing process of evaporative cooling pads. These pads are commonly used in greenhouse and poultry farming applications to provide cooling by harnessing the natural process of evaporation.