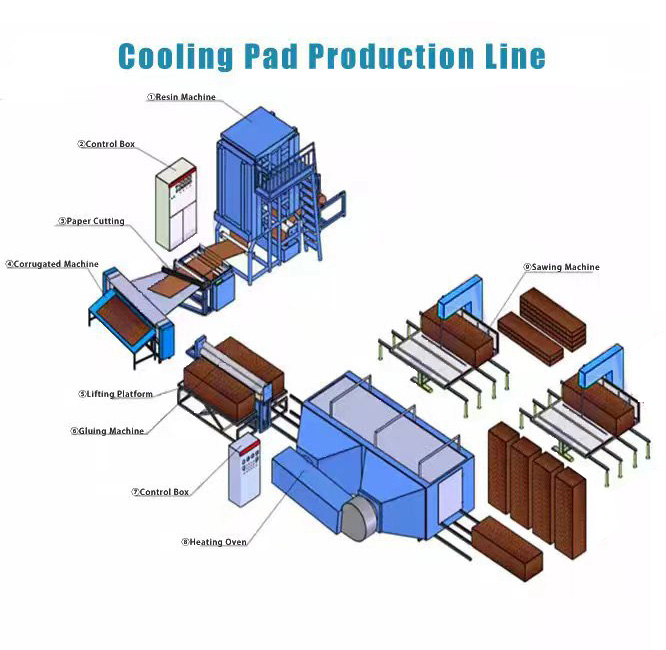

Cooling pad production line cooling pad machine

A cooling pad production line typically involves several machines and processes aimed at manufacturing cooling pads efficiently.

- Duohui

- Qingzhou City,China

- 25 Days

- 1 Set Per Mounth

Details

Material Preparation: Raw materials like cellulose paper or synthetic fiber are prepared for the production process. This may involve cutting or shaping the materials to the desired size.

Glue Application: Adhesive is applied to the material to bond the layers together. This can be done using roller machines or spray systems.

Layering: Multiple layers of material are stacked together to form the cooling pad. These layers are often arranged in a crisscross pattern to maximize surface area for efficient cooling.

Pressing: The layered materials are pressed together to ensure proper bonding and uniform thickness. Hydraulic presses or roller systems are commonly used for this purpose.

Curing: The pressed cooling pads may undergo a curing process to allow the adhesive to set and strengthen the bond between the layers. This can involve passing the pads through heated chambers or allowing them to air dry.

Cutting: Once the cooling pads are fully formed and cured, they are cut into individual pieces of the desired dimensions. Automated cutting machines ensure precision and consistency in the cutting process.

Quality Control: Throughout the production line, quality control measures are implemented to ensure that the cooling pads meet the required standards. This may involve visual inspections, dimensional checks, and performance testing.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)