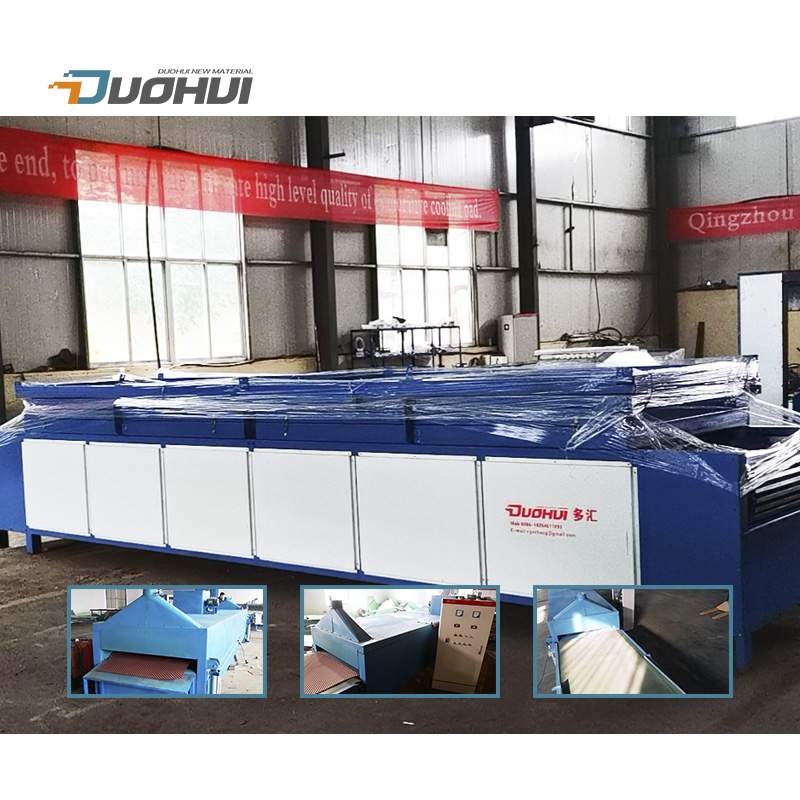

Cooling pad production line for making evaporative cooling pads

Understand the demand for evaporative cooling pads in your target market.

Analyze competitors and their products.

Determine the scale of production based on market demand.

- Duohui

- Qingzhou City,China

- 25 Days

- 1 Set Per Mounth

Details

Work with engineers and designers to create a cooling pad design that optimizes airflow and evaporation.

Consider materials such as cellulose paper, which is commonly used in evaporative cooling pads due to its high absorbency and durability.

Procure high-quality materials required for manufacturing the cooling pads.

Establish relationships with reliable suppliers for consistent material supply.

Acquire or lease a suitable manufacturing facility with adequate space for production and storage.

Install machinery and equipment for the manufacturing process, including:

Cutting and shaping equipment for processing the cellulose paper.

Gluing or binding machines for assembling the cooling pads.

Drying equipment to ensure proper curing of the adhesive.

Implement quality control measures to maintain the consistency and integrity of the cooling pads.

Duohui has more than 8 years of Experience in Manufacturing and R&D of cooling pad production line.

We have developed four energy models:Electric energy; Heat conduction oil energy; Oil and electricity switching; Oil and electricity mixing.And two size:740mm or 1100mm.

DUOHUI company evaporative cooling pads production line has high efficiency and low energy consumption.The service life of the equipment is 15 years.The company can provide a full range of consulting, training and installation services.The whole production line is composed of Resin Machine or Send Machine, Cutting Machine, Transfer Machine, Corrugating Machine,Gluing Machine, Oven Machine, Sawing Machine and so on.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)