Automatic production line for cooling pads same as Munters

--> Reasonable structure, stable operation, high efficiency

--> Increases the heating efficiency, decrease the consumption of electricity

--> High Precision & Performance Stable

--> Easy operation to reduce labor costs

- Duohui

- Qingzhou, China

- 25 Days

- 2 Sets Per Month

Details

Build a system that provides the performance you need, and maximizes the return on your investment.

Professional Machinery, Quality guaranteed, Price reasonable!

We are original and virgin manufacturer in China.

Direct factory develop your satisfied products | One-stop service makes you worry-free after the sale

We provide high-end customized and OEM services.

Cooling Pad Production Line Introduction

Duohui Evaporative Cooling Pad Production Line Machinery is specialized in producing the cooling pad.

Our company can provide a variety of configuration solutions.

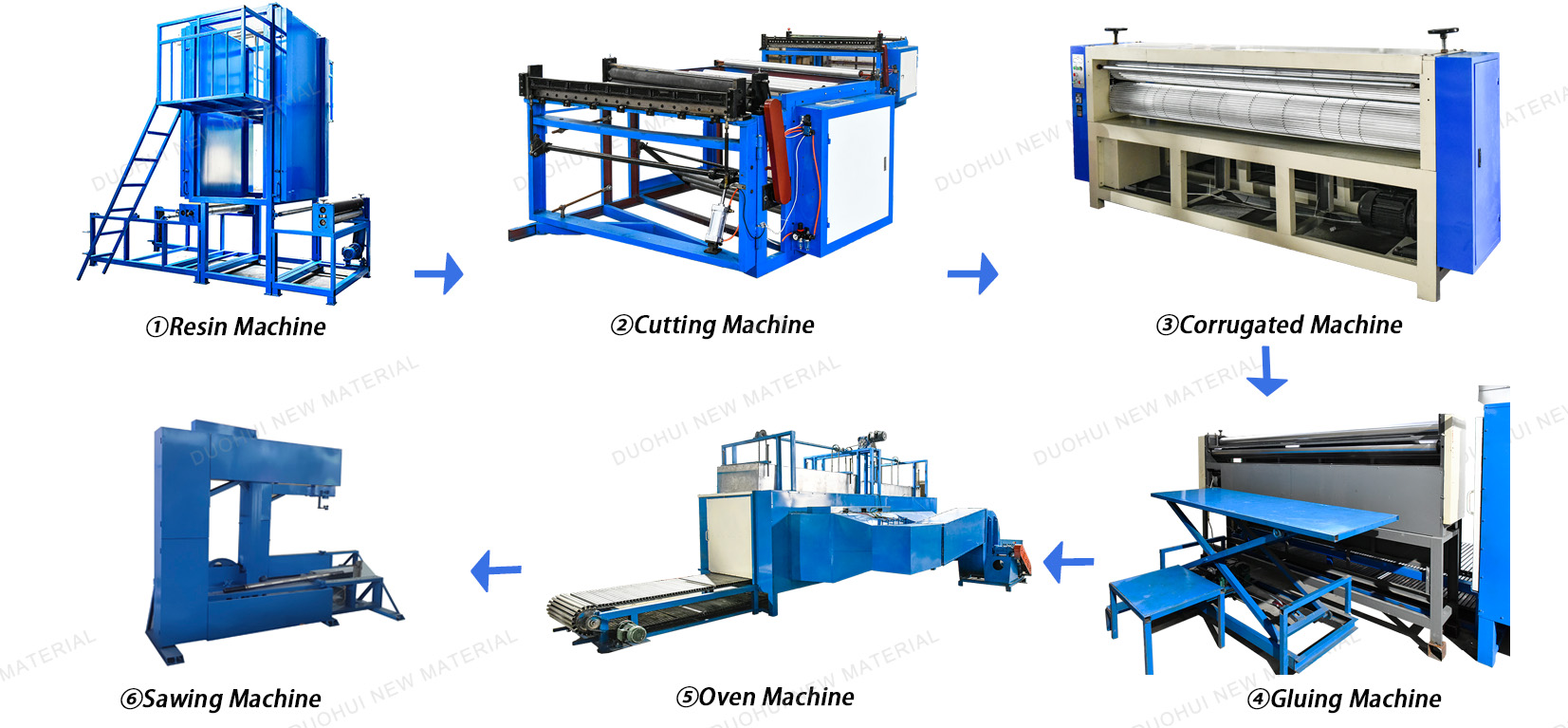

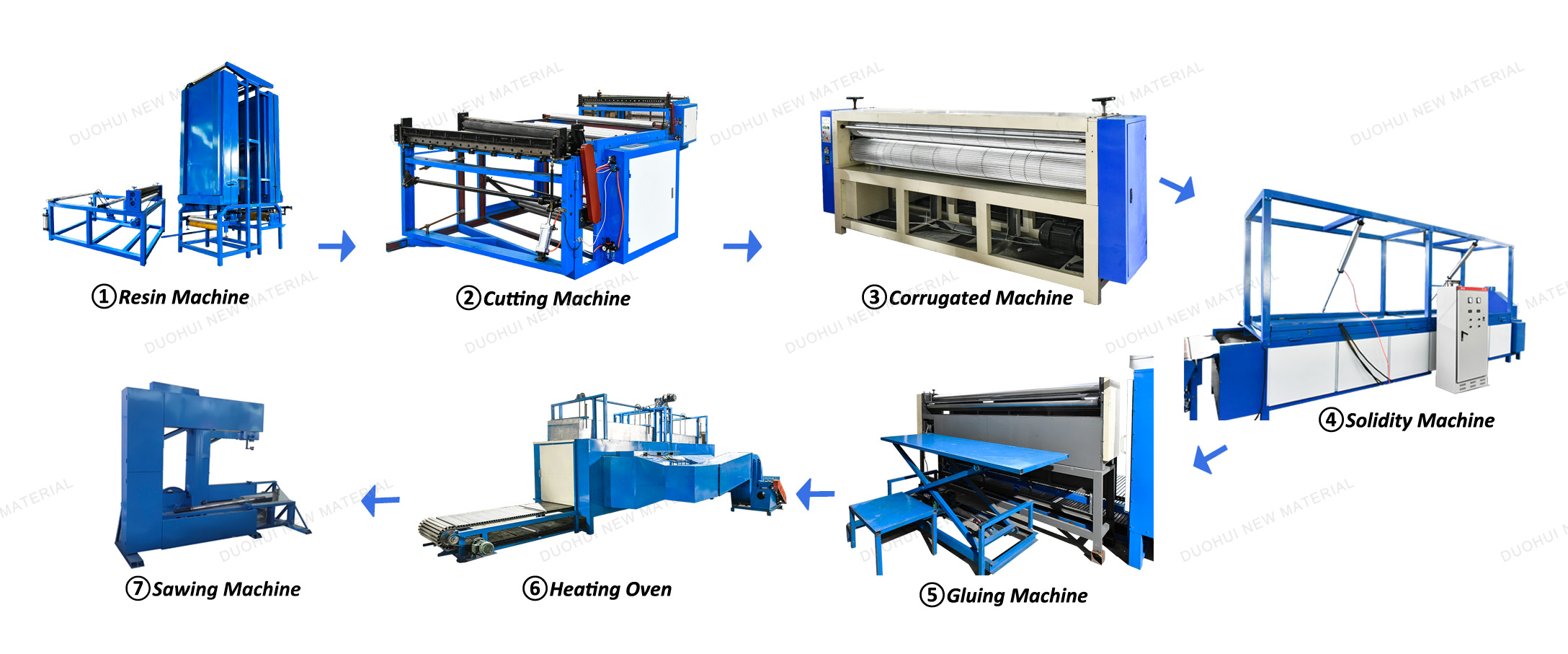

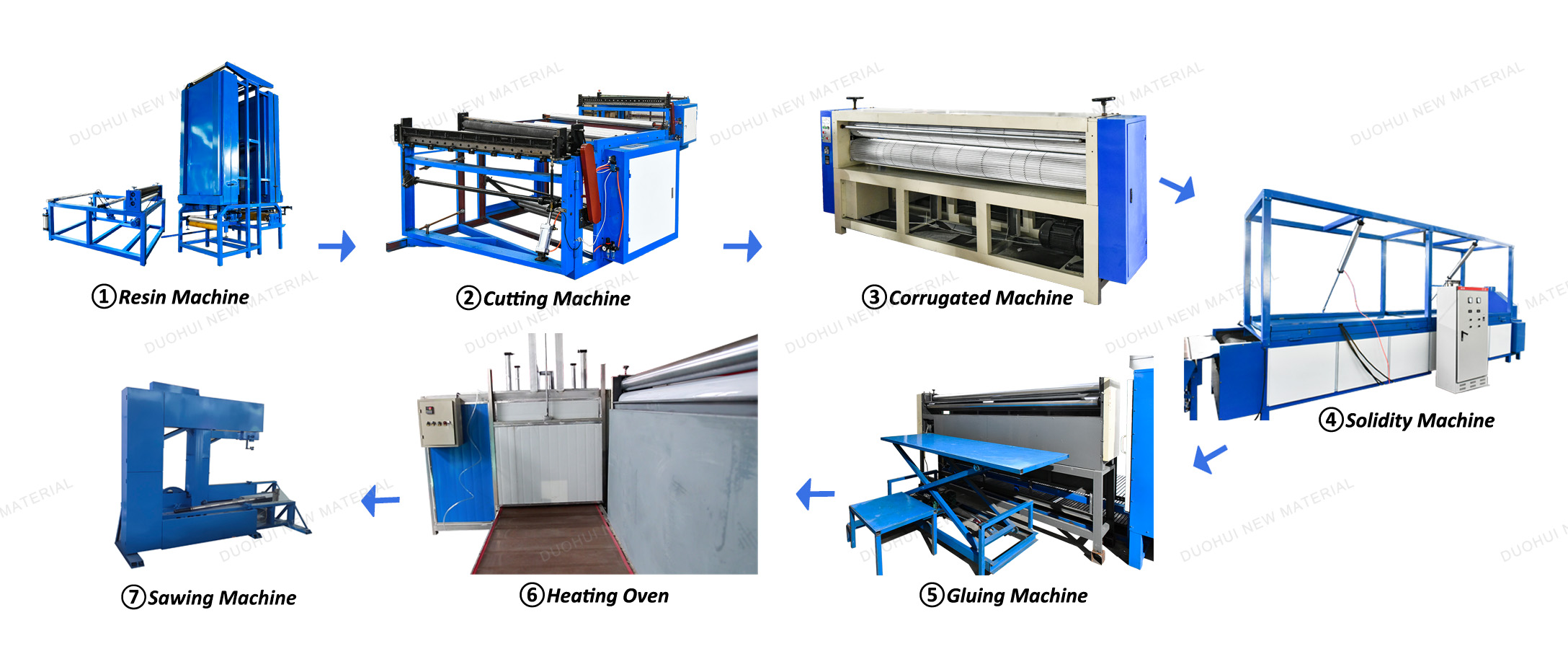

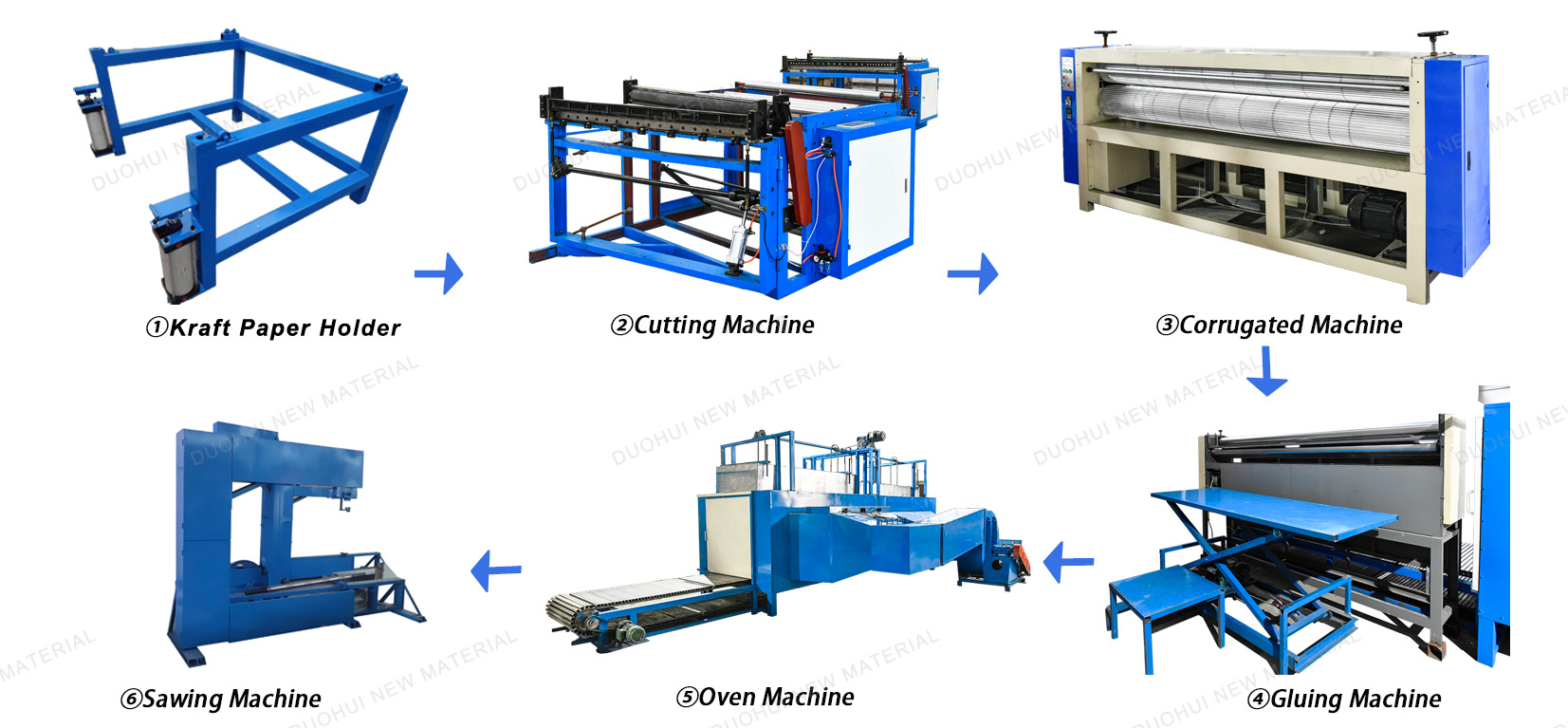

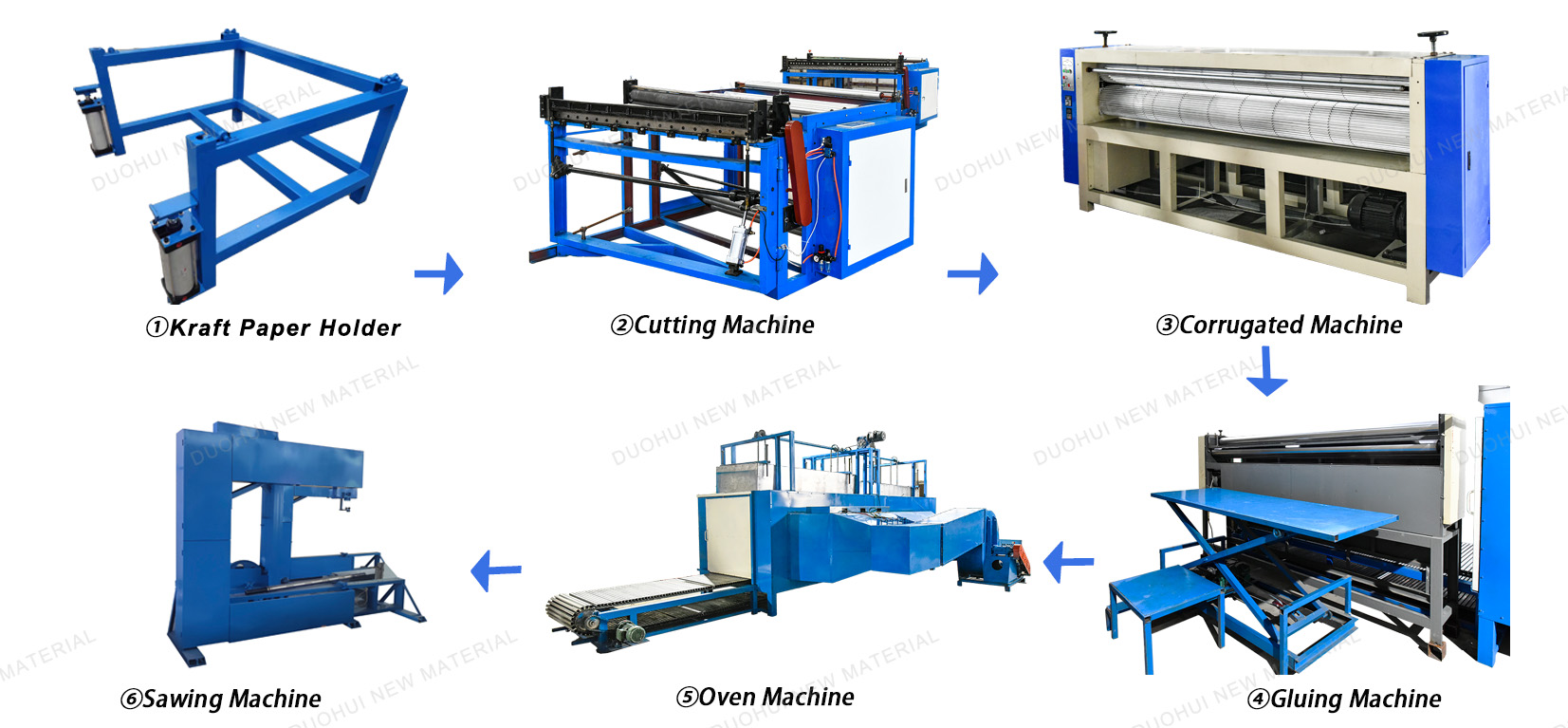

The Production Line mainly includes resin machine, cutting machine, corrugated machine, heating & forming machine, gluing machine, oven/solidifying machine, sawing machine, polishing machine, blending machine and electrical equipment.

We provide complete automatic cooling pad manufacturing equipment & production line with complete consultancy, And training and Installation services.

Multiple configuration combinations

Option A(Use Kraft Paper)

Option B(Use Kraft Paper)

Option C(Use Kraft Paper)

Option A(Use Resin Coated Kraft Paper)

Option B(Use Resin Coated Kraft Paper)

Option C(Use Resin Coated Kraft Paper)

Qingzhou Duohuiyawei Faith Materials Technology Manufacturing Co.,Ltd have strong production capacity.

We can share more profits with our foreign market customer,

and we will provide you with the best quality goods and also the most competitive price support.

Our Advantages

--> Reasonable structure, stable operation, high efficiency

--> Increases the heating efficiency, decrease the consumption of electricity

--> High Precision & Performance Stable

--> Easy operation to reduce labor costs

Evaporative cooling pads production line is the fifth generation product of our company,

which simplifies the operation process, is easier to use and has low procurement cost.

Reasonable structure, stable operation, high production efficiency.

General view of cooling pad production line. The production line covers an area of 200cbm.

Above is all the machines and process for cooling pads production.

This production line need total 5 workers and 1 group leader who control all production line.

The final output capacity of cooling pads is 60cbm per day, one tons paper can output 54/46cbm cooling pads.

Detailed Images

Material Handling: Raw materials such as cellulose fiber, binding agents, and water are transported to the production line. This could involve conveyor belts or automated feeding systems.

Mixing and Forming: The raw materials are mixed together in precise proportions to form the cooling pad material. This mixture is then fed into a forming machine where it is shaped into the desired size and thickness of cooling pads. This process may involve molds or extrusion techniques.

Drying: The formed cooling pads need to be dried to remove excess moisture. This can be achieved through various methods such as hot air drying or infrared drying. The drying process must be carefully controlled to ensure uniformity and quality of the final product.

Cutting and Shaping: Once dried, the cooling pads are cut into individual pieces of the desired dimensions. This can be done using cutting machines equipped with blades or lasers for precision cutting.

Quality Control: Throughout the production process, quality control measures are implemented to ensure that the cooling pads meet the required standards. This may involve visual inspections, measurements of thickness and density, and testing for absorbency and cooling effectiveness.

Packaging: The finished cooling pads are then packaged into boxes or bags for distribution. This can be done automatically using packaging machines equipped with scales and sealing mechanisms.

Automation and Control Systems: The entire production line is controlled by automation systems that monitor and regulate the various processes. Sensors and feedback mechanisms are used to ensure consistency and efficiency in production.

Maintenance and Troubleshooting: Regular maintenance schedules are established to keep the production line running smoothly. Additionally, systems for troubleshooting and resolving issues quickly are put in place to minimize downtime.

By implementing these steps and considerations, you can create an efficient and reliable automatic production line for cooling pads.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)