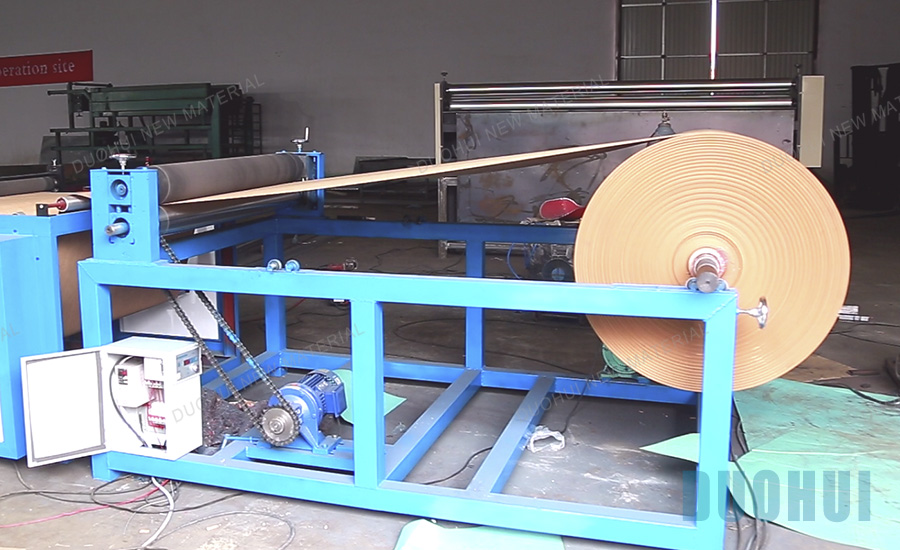

Honeycomb pad machine line evaporative cellulose cooling pad making machine

Setting up a honeycomb pad machine line for making evaporative cellulose cooling pads involves acquiring specific machinery designed to process cellulose paper into honeycomb structured cooling pads.

- Duohui

- Qingzhou City,China

- 25 Days

- 1 Set Per Mounth

Details

Paper Slitting Machine: Cuts large rolls of cellulose paper into narrower strips.

Corrugation Machine: Corrugates the paper strips into a wavy pattern to increase surface area.

Glue Application System: Applies adhesive to the corrugated paper strips.

Laminating Machine: Stacks and bonds multiple corrugated layers together to form a thick pad.

Drying Oven: Cures the adhesive and ensures the pads are thoroughly dried.

Edge Cutting Machine: Trims the edges of the laminated pads to achieve the final dimensions.

Quality Control Equipment

Thickness and Density Measuring Devices: Ensures consistency in pad dimensions and density.

Absorption and Efficiency Testing Machines: Checks the water absorption rate and cooling efficiency of the pads.

Packaging and Handling

Cutting Machine: Cuts the finished pads into standard sizes.

Packaging Machine: Packs the finished pads for transportation.

Conveyor Systems: Transports materials and finished products through different stages of production.

More importantly, We have our own professional design and development department, providing the best pre-sale service and after-sale service.

Sincerely welcome for your visit and technique communication.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)