Honeycomb pad machine line cellulose cooling pad production machinery

2024-07-01 10:15

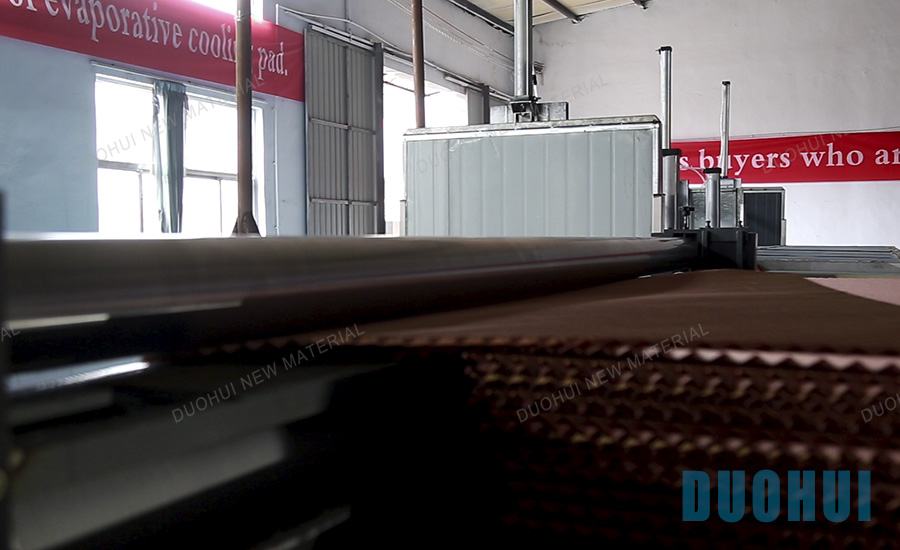

Setting up a honeycomb pad machine line for making evaporative cellulose cooling pads involves acquiring specific machinery designed to process cellulose paper into honeycomb structured cooling pads.

Material Preparation

Cellulose paper rolls are loaded into the machine line.

Paper is treated with chemicals to enhance durability and resistance to rot and fungus.

Paper Slitting

The treated cellulose paper is slit into narrow strips suitable for corrugation.

Corrugation

Slit paper strips are passed through the corrugation machine to form a wavy pattern, increasing the surface area for evaporation.

Glue Application and Laminating

Corrugated strips are coated with adhesive and laminated together in multiple layers to form a thick honeycomb structure.

Drying

The laminated pads are dried in an oven to cure the adhesive and ensure structural integrity.

Cutting and Trimming

Dried pads are cut and trimmed to the required dimensions.

Quality Control

Finished pads are tested for thickness, density, water absorption, and cooling efficiency.

Packaging and Storage

Quality-approved pads are packed and stored for distribution.

Key Considerations

Machinery Quality

Invest in high-quality machinery to ensure consistent production and product quality.

Raw Material Quality

Use high-quality cellulose paper and adhesives to ensure the durability and efficiency of the cooling pads.

Process Optimization

Continuously monitor and optimize the production process to improve efficiency and reduce waste.

Regulatory Compliance

Ensure the production line complies with local regulations regarding safety, environmental impact, and product standards.

Skilled Workforce

Train your workforce to operate the machinery effectively and maintain quality control throughout the production process.

By following these guidelines and setting up the appropriate machinery, you can establish an efficient and high-quality production line for honeycomb evaporative cellulose cooling pads.

Get the latest price? We'll respond as soon as possible(within 12 hours)