Wet Curtain Cooling Pad Production Making Equipments

Quality is our foundation and great service is always our mission.

From raw materials to production and processing one-stop services the whole industry chain.

We are committed to providing the best quality with the lowest environmental impact.

Build a system that provides the performance you need,

and maximizes the return on your investment.

Professional Machinery, Quality guaranteed, Price reasonable!

Reasonable structure, Stable running, High efficiency!

- Duohui

- Qingzhou, China

- 20 Days

- 2 Sets Per Month

Details

Build a system that provides the performance you need, and maximizes the return on your investment.PERFORMANCE YOU CAN COUNT ONDUOHUI offers high-end customized servicesThe company can provide a variety of configuration solutions

Products Description

Kraft Paper Cooling Pads Production Equipment

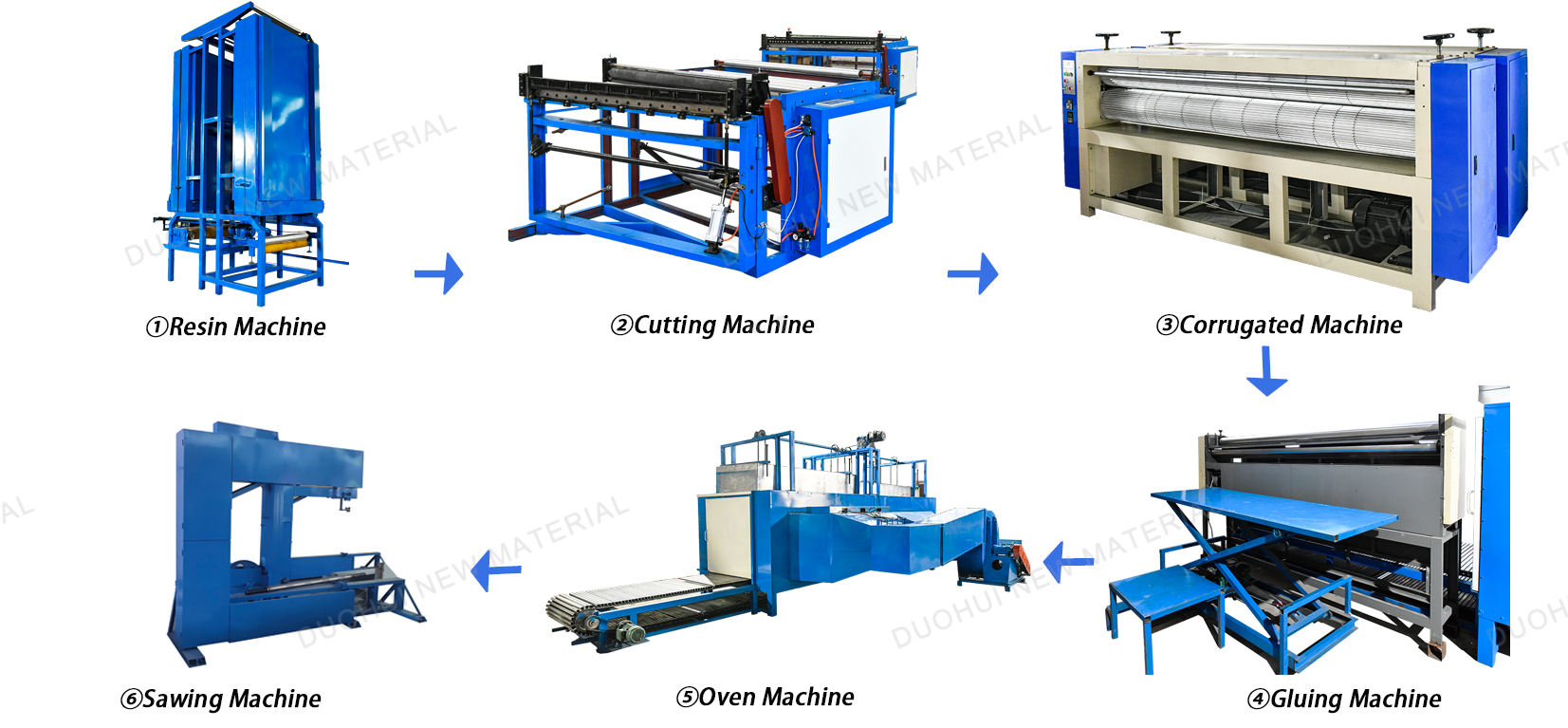

Duohui Evaporate Cooling Pad Production Line Machinery is specialized in producing the cooling pad. It includes resin machine, cutting machine, corrugated machine, heating & forming machine, gluing machine, oven/solidifying machine, sawing machine, polishing machine, blending machine and electrical equipment.

We provide complete automatic cooling pad manufacturing machine, equipment and production line with complete consultancy, training and Installation services.

Product Specifications

No. | Product Name | Voltage | Power | Frequency |

1 | Resin Machine | 380 v | 120 kw | 50 Hz |

2 | Paper Cutting Machine | 380 v | 0.5 kw | 50 Hz |

3 | Corrugating Machine | 380 v | 30 kw | 50 Hz |

4 | Solidify Machine(Optional) | 380 v | 60 kw | 50 Hz |

5 | Gluing Machine | 380 v | 1.5 kw | 50 Hz |

6 | Heating Oven | 380 v | 80 kw | 50 Hz |

7 | Sawing machine | 380 v | 3 kw | 50 Hz |

#7090 / #6090 / # 5090 three models of cooling pads can be produced.Configurations can be customized to satisfy your various needs.

Product Advantage

--> Reasonable structure, stable operation, high efficiency

--> Increases the heating efficiency, decrease the consumption of electricity

--> High Precision & Performance Stable

--> Easy operation to reduce labor costs

Evaporative cooling pads production line is the fifth generation product of our company, which simplifies the operation process, is easier to use and has low procurement cost.Reasonable structure, stable operation, high production efficiency.

General view of cooling pad production line. The production line covers an area of 200cbm. Above is all the machines and process for cooling pads production. This production line need total 5 workers and 1 group leader who control all production line. The final output capacity of cooling pads is 60cbm per day, one tons paper can output 54/46cbm cooling pads.

Detailed Images

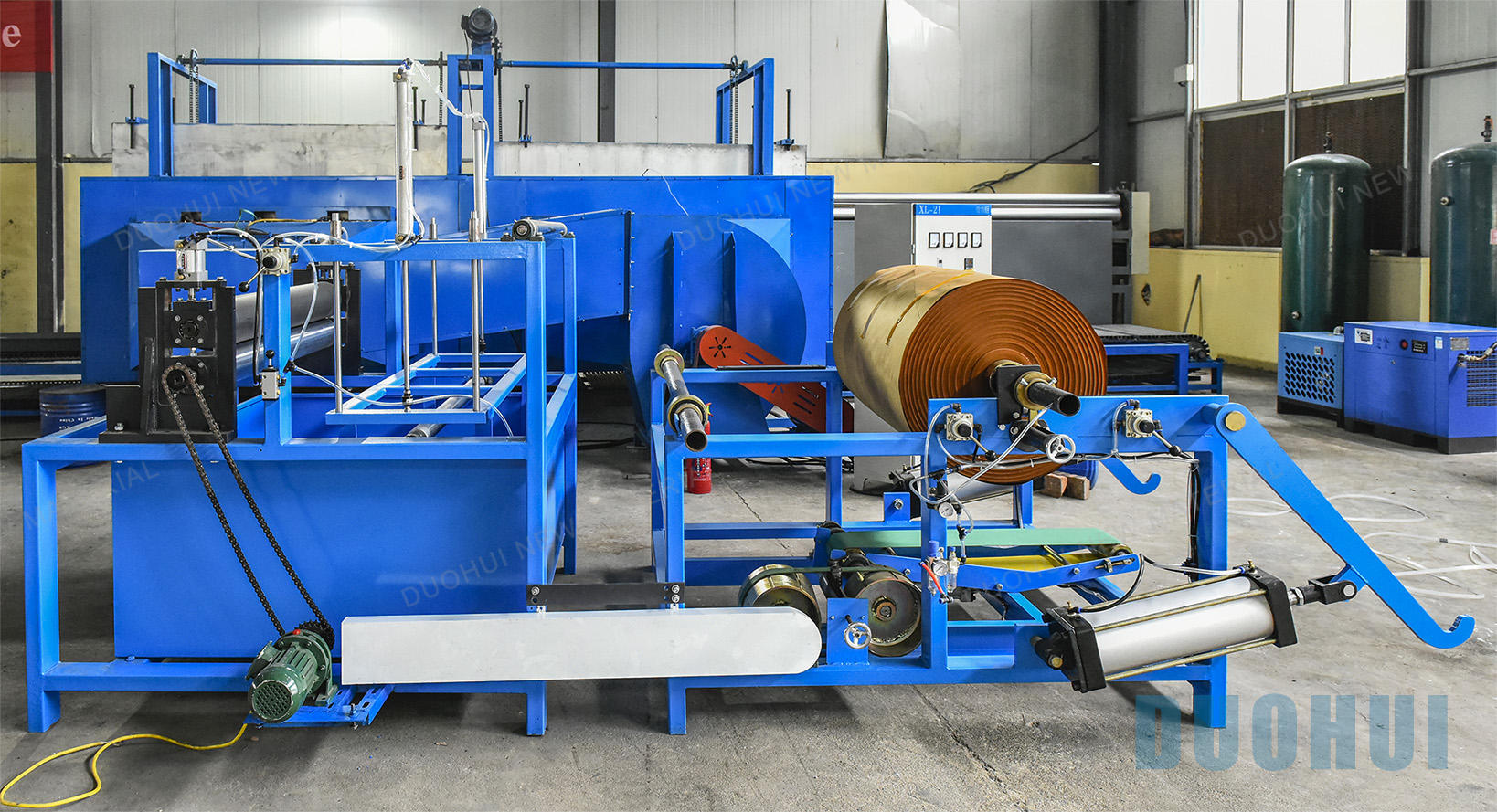

Resin Machine

1. High quality stainless steel to ensure never rust under high temperature condition.

2. Adopt 8 digital control, easy operation, uniform temperature, higher heating efficiency, lower electricity consumption to improve cooling pad quality.

2. Adopt 8 digital control, easy operation, uniform temperature, higher heating efficiency, lower electricity consumption to improve cooling pad quality.

Paper Roll Holder

The paper feeder can be used with special cooling pad resin coated paper, and our company can complete the first step of the cooling pads, so as to save the relatively complicated process of resin machine, reduce the cost and improve the production efficiency.

Paper Cutting Machine

Optimized frame design, precision machining, stable performance, strong and durable

Corrugated Machine

Adopt wear resistant bushing which is made of special material, withstand high temperature, longer service life.

Gluing Machine

Widen the gluing machine,raise the working efficiency,lower the working hardness.The gluing machine has the advantages of fast curing speed, high bonding strength, simple operation, convenience, strong versatility and good aging resistance.

Heating Oven

Inner circulating heating oven to achieve multi-direction heating, quick temperature rising.

High efficiency ,lower drying cost.

Product Tag

Get the latest price? We'll respond as soon as possible(within 12 hours)